It has been a tough couple of years for manufacturers of all stripes around the world. First came the pressures of rebuilding supply chains amid Brexit. This was followed by an even wider restructuring due to the pandemic, only for manufacturers to get further impacted by sharp rises in costs due to inflation. Between the pain and the recovery, many manufacturers rebuilt their resilience back to pre-pandemic levels, while others surrendered to the volatility of the supply chain landscape.

According to insolvency reports based on Creditsafe’s global manufacturing database, we were able to compare the year-on-year changes in the global and regional insolvencies across some major manufacturing economies in North America and Europe and understand what it means for manufacturers this year.

The report shows that as inflation slowly begins to settle across the world, there was a small dip of 9% in global manufacturing insolvencies in February 2024 compared to the same time last year. However, upon taking a closer look into regional insolvencies within the manufacturing sector, we found that this illusion of reduced insolvencies was primarily brought forth due to the resilience of economies like the UK & USA. In fact, it concealed a sharp rise in insolvencies across France, Germany, and Italy – highlighting how some manufacturing economies are still reeling from the aftereffects of the pandemic and the current geopolitical landscape.

Manufacturers are not out of the woods yet. But could this be an opportune moment for many to assess some of the damage sustained and how they can prepare for possible disruptions, cashflow crunches, and insolvencies during this year?

How have insolvencies impacted some of the largest manufacturing economies so far in 2024?

Growing turbulence for manufacturers in Germany, France & Italy

Disruptions in the manufacturing sector impacted Europe’s top three economies the most last year. Germany’s manufacturing sector first took a hit from the sharp increase in energy prices, which significantly halted industrial production. While insolvency figures remained stagnant and within a range of 1,000 businesses between February 2023 and February 2024, industrial production is expected to further decline by 1.5% in Europe’s largest economy in 2024, which may cause another spike in manufacturers going under.

Italy has faced a similar predicament. Sometime mid-last year, Italy plunged into a deep manufacturing recession after months of struggling with inflationary jumps, steep energy costs, and a massive slowdown in consumer spending and investment.

A vicious cycle of worsening inflation led to slower demand and production, eventually resulting in a hiring freeze in the labour market that directly impacted Italy, Europe’s third-largest manufacturing sector. Eventually, this set off a downward spiral of production and manufacturing, contributing to over 9,000 insolvencies since February 2023.

The shrinking Italian manufacturing sector has also directly impacted neighbouring countries such as France, where we observed a sharp spike in insolvencies—from 4000 in February 2023 to 5,400 in February 2024. France, being the Eurozone’s second-largest economy, has suffered similar blows to its GDP as Italy, resulting in slow purchase activity, drops in productivity, and a hiring freeze.

The enduring slowdown in the manufacturing sectors of Germany, France, and Italy, the three largest European economies, has sent shockwaves through many surrounding European regions and even all the way across the Atlantic.

Slow and steady relief to inflationary pressures in US markets

The small dip in US manufacturing insolvencies from 3,500 in 2023 to 3000 in 2024 is a reflection of the US’ current economic climate, where manufacturers may be experiencing momentary relief from the pressures of inflation. Still, they are not out of the woods yet – especially, as cost rise and interest rates remain high.

The election will determine whether the number of manufacturing insolvencies will stabilize or spike this year.

The pressures of cost mitigation are further exacerbated by the looming presidential election. The election will determine whether the number of manufacturing insolvencies will stabilise or spike this year. The shifting political climate is particularly of concern to the fuel and petrochemical manufacturers with the passing of new climate laws like California’s vehicle emissions standards which requires all new cars sold from 2035 to produce zero emissions.

The rule, compounded by many states placing bans on gas-powered vehicles, is encouraging automakers to transition more rapidly to Electric Vehicles (EVs)) – causing a huge rift in the supply chain between automotive manufacturing and fuel petrochemical manufacturers.

Stabilizing conditions in UK & Ireland

When the cost of raw materials sharply increased during 2022 and 2023, it drove many UK & Ireland-based manufacturing firms to bankruptcy last year. These cost increases hit food manufacturers particularly hard, with many unable to keep up with rising costs in the aftermath of the Ukraine-Russia war. When energy and fuel costs spiked, it snowballed into a raw material shortage, and many suppliers increased their costs without any sufficient buffer time to recover.

However, in 2024, British and Irish manufacturers are finally able to come up for air with a mild uptick in domestic demands and a reduction in energy costs. Both insolvencies and job losses are slowing tapering off in the manufacturing sector in the UK & Ireland. Creditsafe’s data showed that the year-on-year UK & Ireland insolvencies together remained within the same range of 250 and 253 – showing gradual stability in their manufacturing sectors now compared to the previous years.

What might cause another spike in manufacturing insolvencies in 2024?

On the surface, rising costs, new regulations, and geopolitical tensions right off the back of COVID-19 may appear to be the main drivers behind the painful squeeze in manufacturing margins in the last few years. However, in order to dig deeper into the myriad global shifts that contributed to the recent spike in insolvencies and what challenges may lie ahead, we spoke Assistant Professor in Operations and Supply Chain Management at Trinity Business School, Dr. Isilay Talay, who helped us to pinpoint the top global manufacturing risks to watch out for in 2024:

1. Climate change policies & cashflow:

Over the past five years, flooding has emerged to be a significant business risk for many manufacturers, prompting them to relocate operations away from vulnerable, low-lying regions like South Asia and many parts of South America.

However, it isn’t just the physical climactic conditions that have shot up costs for manufacturers; the recent climate change policies that many countries have passed to combat emissions and preserve air quality have also equally impacted costs and particularly cashflow for manufacturers as well as their ‘tier-n’ suppliers.

“When new climate change policies are passed, it’s often the tier-n suppliers that suffer. Take for example, countries with large automotive manufacturing markets, that still don’t produce electric vehicles as competitively as the US or China, all the suppliers that are at the upstream of the supply chain suffer, when new emission policies are passed,” said Talay.

Dr. Talay points out a common cost-shifting strategy that large retailers use when costlier green technologies are introduced, or the cost of inputs begins to rise. Instead of increasing prices for downstream customers to pay up, they shift the costs upstream for suppliers to take the hit. However, with no cash going up the supply chain, it sometimes renders their own manufacturers and suppliers insolvent and backfires on them with a complete supply chain breakdown.

2. Paying the price for greener pastures & new sources of procurement

The ongoing wars between Russia-Ukraine and Israel-Hamas have prompted many manufacturing giants to shift production from these war-inflicted regions to safer, ‘friendlier’ regions closer to their shores or the countries that maintain harmonious trade agreements with their own – such as Mexico. Similarly, with China’s deteriorating relationships with many global economies, Vietnam has gained a rising status as a host for production outlets for many US manufacturers of mining quarrying and automotive parts.

The increase in transportation costs due to shipping routes becoming longer, more complex and with the involvement of more stakeholders is proving to be a double-edged sword for both manufacturers and their suppliers.

However, the perils continue even after shifting base. For many manufacturers, cost-cutting is proving difficult at a time when they must constantly rebuild supply chains in the face of the war. The increase in transportation costs due to shipping routes becoming longer, more complex and with the involvement of more stakeholders is proving to be a double-edged sword for both manufacturers and their suppliers.

“It’s not only the Ukraine-War but the Red Sea attacks that’s pushing major shipping lines to traverse around the African subcontinent. This has significantly bumped up costs for manufacturers and decreased margins for suppliers,” said Dr. Talay.

"It’s difficult for suppliers to find a customer that would give them advance payments. The pressure keeps mounting on the supplier who needs to chart a reroute and take the risks of a longer route into account while already sharing their margins with the transportation company."

"And on top of that, if in case the materials are delivered late, their payments are further postponed, again clogging up the cashflow. Similarly, at the manufacturer’s end, if materials are delivered late or not delivered at all, it would cause a serious disruption to their production capabilities along with the supply chain.”

Dr. Talay highlights a significant challenge numerous suppliers and manufacturers face: the lack of strong risk management systems and processes. This deficiency leaves both suppliers and manufacturers exposed to the harsher consequences of supply chain disruptions, transportation delays, and cash flow problems.

3. Increasing risk of sanctions & ethical breaches

‘Elephants fight, but it’s the grass that gets trampled’ is a common saying in Dr. Talay’s native language, Turkish, that poignantly captures how most manufacturers were adversely impacted by the war-related sanctions.

The use of economic sanctions is nothing new, but the sweeping degree and number of sanctions issued after the Russian invasion of Ukraine have left manufacturers exposed to the risk of accidentally working with sanctioned suppliers or unknowingly associating with sanctioned beneficial owners. Sanctions have not only become a growing compliance headache for many SME manufacturers who are finding it hard to fill the knowledge gap on sanctions but also for large manufacturers who manage complex supply chains and payment routes and can have a long-term impact on their suppliers when exposed to sanction breaches.

“Large manufacturers needn’t be insolvent to cause a spike in insolvencies. Even when they are impacted by a sanctions breach, and their profits and market shares decrease, it immediately creates a ripple effect on all of their various suppliers everywhere,” said Dr. Talay on how large manufacturers being exposed to penalties and reputational risks can cause a direct impact on SME manufacturing insolvencies.

How can manufacturers navigate risks better in 2024?

Large manufacturers needn’t be insolvent to cause a spike in insolvencies, even when they are impacted to a sanctions breach... it immediately creates a ripple effect on all of their various suppliers everywhere

‘Supply chain management is not only limited to the physical flow of goods, it also depends on the flow of funds and flow of information,’ says Dr. Talay on what manufacturing firms need to arm themselves against the predicted disruptions this year.

‘How manufacturers use information to predict and manage supply chain disruptions will play a huge role in their success and failure this year.’

Creditsafe has been helping over 20,000 manufacturers across the globe with it’s robust international and local credit reports that hosts in-depth financial and payment data on companies across 200 countries. The Creditsafe business checks provide a 360 degree approach to risk management by covering both financial and reputational risks for manufacturers:

- Increasing visibility against reputational risk: Creditsafe’s due-diligence platform KYC Protect helps suppliers dive deep into the complex ownership structures of the businesses they’re supplying to. With just a few clicks, one can establish who the directors, shareholders, and UBOs are in a business and screen them against anything from sanctions, enforcement, politically exposed persons, insolvency registries, and many more risk categories.

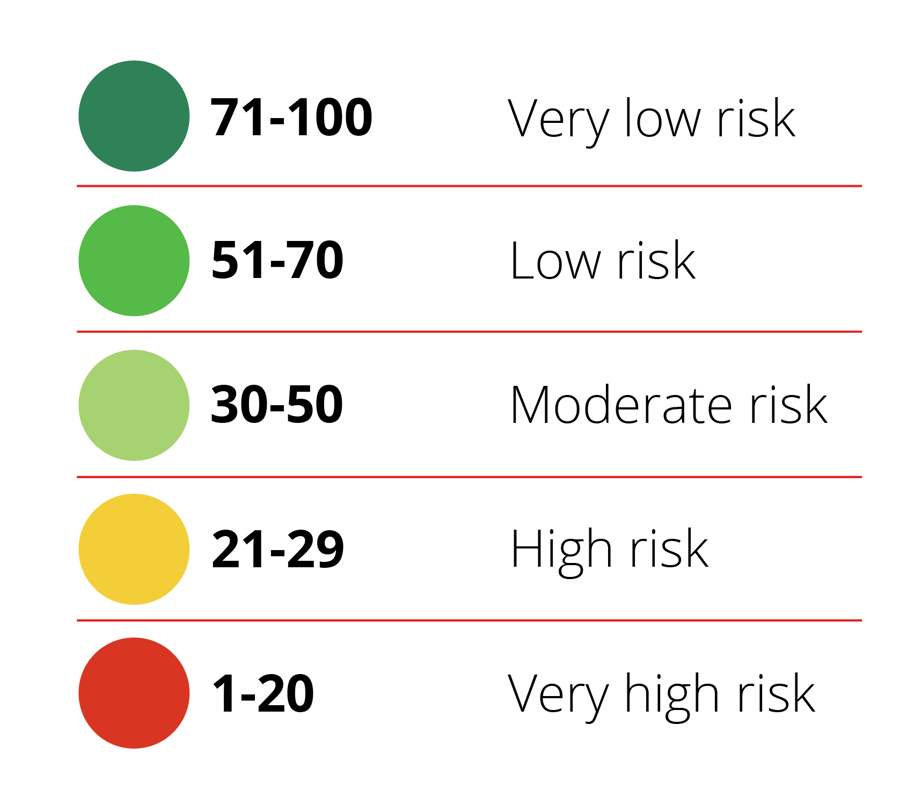

- Increasing transparency against financial risk: When running due diligence checks on suppliers, manufacturers can use Creditsafe business report data to deep-dive into customers' financial behaviour by screening them for multiple data points like risk score, days-beyond-terms score, and much more to screen their suppliers for financial risk before they’re onboarded.

The global manufacturing insolvencies may have reduced by 9% in the first quarter this year, but some of the world’s largest manufacturing economies continue to suffer and show red flags for disruption during the rest of the year.

For many, there’s nothing too surprising in these figures, given the economic context of wars, climactic disruptions, and geopolitical tensions, but what’s concerning is how manufacturers will respond to the up-and-coming challenges in 2024. Whether or not manufacturers will come out of the woods largely depends on how they use data to increase their supply chain transparency. This will largely hold the key to their success and failure amid the current supply chain landscape of simmering geopolitical tensions, sanctions, and rising sea levels.